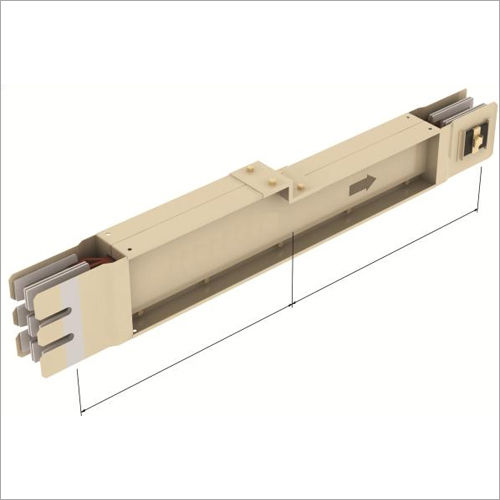

Sandwich Busbar Tunking System

Price 3148-3523 INR/ Kilograms

Sandwich Busbar Tunking System Specification

- Feature

- Compact, Pre-fabricated, Maintenance-free, Expansion Flexible

- Operating Temperature

- -5C to 40C

- IP Rating

- IP55/IP65

- Insulation Material

- Epoxy Resin/Polyester Film

- Shape

- Rectangular

- Connector Type

- Bolt/Plug-in Joint

- Humidity %

- Up to 95% non-condensing

- Power Factor

- >0.95

- Surface Finish

- Powder Coated

- Mounting Type

- Ceiling or Wall Mounted

- Overheating Protection

- Yes, Integrated

- Efficiency

- 99%

- Product Type

- Sandwich Busbar Trunking System

- Application

- Industrial Power Distribution, Commercial Buildings, Data Centers

- Protection Level

- High insulation, Fire Resistant

- Frequency (MHz)

- 50/60 Hz

- Rated Voltage

- 415 V, up to 690 V

- Energy Consumption

- Low Line Losses

- Output Type

- Electrical Power Distribution

- Color

- Silver Grey (Housing), Color coded phases

- Dimension (L*W*H)

- Standard: 2500 mm Length; Width and Height varies as per rating

- Weight

- Depends on configuration (approx. 20-40 kg/m)

- Size

- Varies as per current rating (100A to 4000A)

- Input Voltage

- 380/415/690 V

- Phase

- Three Phase

- Connection Type

- Bolt-on/Plug-in

- No Of Poles

- 3, 4, or 5 Poles

- Material

- Copper or Aluminium Conductors with Aluminum Alloy Housing

- Busbar Enclosure

- Extruded Aluminum Alloy

- Voltage Drop

- Low, typically <2.5mV/A/m

- Custom Lengths

- Available on request

- Earthing System

- Dedicated earthing conductor

- Environmental Suitability

- Indoor/Outdoor

- Installation

- Simple, tool-free plug-in tap-off boxes

- Tap-off Points

- At every 0.5 to 1.0 meter interval

- Fire Resistance

- Complies with 850°C glow wire test

- Corrosion Resistance

- Resistant to humidity and industrial atmosphere

- Mechanical Strength

- High mechanical strength to withstand vibration and thermal expansion

- Short Circuit Withstand Capacity

- Up to 50 kA for 1 sec

- Joint Tightness

- Double-headed bolts ensure reliable, maintenance-free joints

Sandwich Busbar Tunking System Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Supply Ability

- 15000 Kilograms Per Month

- Delivery Time

- 1 Months

About Sandwich Busbar Tunking System

Robust Power Distribution Solution

Engineered for high mechanical strength, the Sandwich Busbar Trunking System withstands vibration, thermal expansion, and extreme operating conditions. Its extruded aluminum alloy enclosure and integrated fire-resistant features guarantee safety and durability.

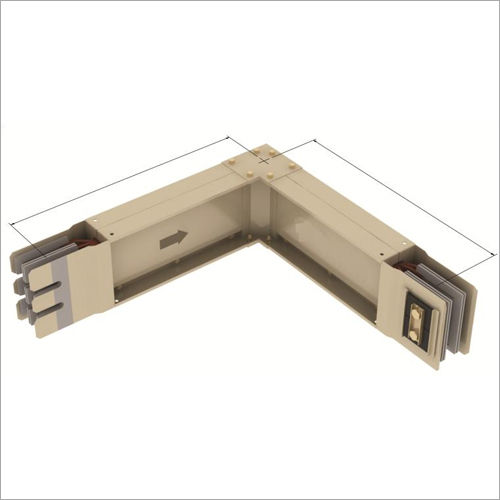

Flexible and Efficient Installation

The trunking system enables rapid deployment with tool-free plug-in tap-off boxes and bolt-on joints, making it suitable for both ceiling and wall mounting. Custom lengths and modular design simplify expansions and upgrades, tailoring the system to project requirements.

Superior Safety and Reliability

Compliance with rigorous standards such as the 850C glow wire test ensures fire resistance. With dedicated earthing conductors, low voltage drop, and high insulation, the system provides dependable electrical performance in diverse environments.

FAQs of Sandwich Busbar Tunking System:

Q: How is the Sandwich Busbar Trunking System installed?

A: Installation is straightforward due to plug-in tap-off boxes and bolt-on connections, allowing for quick, tool-free assembly on ceilings or walls. Standard lengths are supplied, and custom dimensions are available upon request to suit specific site needs.Q: What environments is this busbar system suitable for?

A: Its extruded aluminum alloy housing offers corrosion resistance and an IP55/IP65 rating, making it ideal for indoor or outdoor applications, including industrial facilities, commercial complexes, and data centers across India.Q: When should I use a Sandwich Busbar Trunking System over traditional cabling?

A: Busbar trunking is recommended where high reliability, ease of expansion, low maintenance, and superior mechanical strength are needed. It is optimal for installations requiring compact, fire-resistant, and energy-efficient power distribution.Q: Where can tap-off points be placed in this system?

A: Tap-off points are spaced at intervals of 0.5 to 1.0 meter, offering flexibility for power distribution to different areas within a facility, and simplifying future modifications or expansions.Q: What is the process for expanding the busbar trunking system?

A: Expansion is facilitated by its modular, pre-fabricated design. Additional lengths and branches can be connected using bolt-on or plug-in joints, maintaining high mechanical strength and electrical integrity throughout the system.Q: How does the system enhance safety and fire protection?

A: Double-headed bolts ensure maintenance-free joints, while the enclosure satisfies fire safety standards, including the 850C glow wire test. Dedicated earthing conductors and high insulation levels further protect against electrical hazards.Q: What are the main benefits of using this busbar system in industrial and commercial applications?

A: Users gain from high efficiency (99%), low line losses, robust short circuit withstand capacity, easy installation, reliable operation under varying temperatures and humidity, and simplified maintenance, ensuring dependable power distribution.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Busbar Trunking System Category

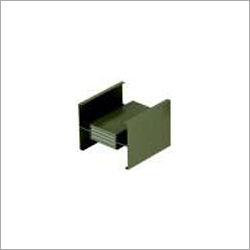

Sandwich Busbar Reducer

Price 3148-3523 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Product Type : Sandwich Busbar Reducer

Application : Electrical Power Distribution, Panel Boards, Switchgears

Phase : Three Phase

Overheating Protection : YES

Conventional Busbar Flatwise Elbow

Price 3148-3523 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Product Type : Conventional Busbar Flatwise Elbow

Application : Electrical Panel, Distribution Boards

Phase : Three Phase

Overheating Protection : YES

Air Insulated Busbar Tunking System

Price 3148-3523 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Product Type : Air Insulated Busbar Trunking System

Application : Industrial, Commercial Power Distribution

Phase : 3 Phase

Overheating Protection : Other, Available with Temperature Sensors

Sandwich Busbar Edgewise Elbow

Price 3148-3523 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Product Type : Sandwich Busbar Edgewise Elbow

Application : Electrical panels, switchgear busbar trunking systems

Phase : Three Phase

Overheating Protection : YES

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry