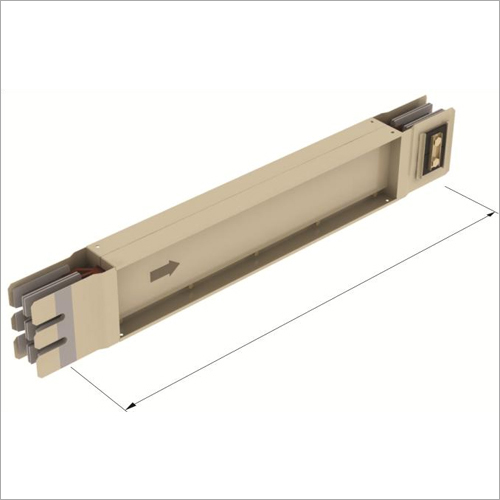

Air Insulated Busbar Tunking System

Price 3148-3523 INR/ Kilograms

Air Insulated Busbar Tunking System Specification

- Insulation Material

- Air insulated with Supports/Barriers

- Surface Finish

- Electrostatically Powder Coated

- Connector Type

- Bolted/Plug-in Type

- Efficiency

- >99%

- Feature

- Modular, Expandable, Low Voltage Drop

- IP Rating

- IP54/IP55

- Mounting Type

- Horizontal or Vertical Wall/Floor/Ceiling Mountable

- Humidity %

- 95% RH

- Power Factor

- >0.95

- Operating Temperature

- -10C to +55C

- Shape

- Rectangular

- Overheating Protection

- Available with Temperature Sensors

- Product Type

- Air Insulated Busbar Trunking System

- Application

- Industrial, Commercial Power Distribution

- Protection Level

- Fully Enclosed, Shrouded Live Parts

- Frequency (MHz)

- 50/60 Hz

- Rated Voltage

- 415V/690V AC

- Energy Consumption

- Low (distribution application)

- Output Type

- Linear Power Distribution

- Color

- Light Grey (RAL 7035)

- Dimension (L*W*H)

- Custom (typical section: 100x150mm, Lengths: 3-4m per section)

- Weight

- Depends on length and current rating (typically 10-30 kg/m)

- Size

- Rated up to 6300A

- Input Voltage

- 415V AC

- Phase

- 3 Phase

- Connection Type

- Bolted Clamp or Plug-in Joint

- No Of Poles

- 3 or 4

- Material

- Aluminium or Copper Conductors, Powder Coated Steel Enclosure

- Busbar Support

- Halogen-Free, High Dielectric Strength Supports

- Accessories

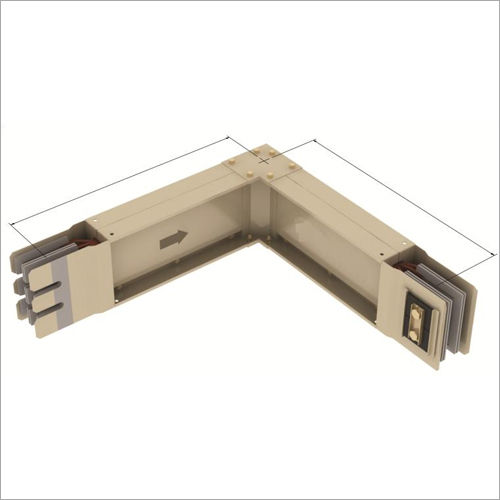

- Elbows, Tee Pieces, End Covers, Hangers

- Customization

- Available for Ampere Ratings, Length, Outlet Types

- Maintenance

- Minimal, Tool-Free Tap Off Possible

- Installation

- Quick and Flexible, Pre-Fabricated Sections

- Tap Off Boxes

- Plug-in/Fixed type, up to 800A

- Surface Treatment

- 7-Tank Process prior to Powder Coating

- Short Circuit Rating

- Up to 70 kA for 1 second

- Mechanical Strength

- High, Rigid Design

- Temperature Rise

- Within IEC 61439 Permissible Limits

- Environmental Suitability

- Indoor and Outdoor (with IP66 on request)

- Conductor Type

- Drawn Electrolytic Copper or Aluminium Conductors

- Insulation Voltage

- Up to 1000V

- Earth Continuity

- Integral Earth Busbar

- Fire Resistance

- Tested as per IEC 60331

Air Insulated Busbar Tunking System Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Supply Ability

- 15000 Kilograms Per Month

- Delivery Time

- 1 Months

About Air Insulated Busbar Tunking System

Ganpati Electricals Pvt. Ltd. is a business partner of Larsen & Toubro for Bus Bar Trunking System, which is used in hotels, data centers, hospitals, airports, industries, factories, apartments etc. Electrical busbar systems are a modular approach to electrical wiring.

Busbar Trunking System is a prefabricated electrical distribution system consisting of busbars in a protective enclosure, including straight lengths, fittings, devices and accessories. These are mainly of two types namely Air-Insulated Trunking Busbar System and Sandwich Trunking Busbar System.

Sandwich Busbar Trunking System is epoxy insulated and used for transferring 400A to 6300A current for up to a maximum of 1000V. Compaired to this Conventional Busbar Trunking System is air insulated and is used for 100-400A current for upto a maximum of 415V. Besides these two, there comes also air-insulated Medium Voltage Busbar Trunking System for 100A to 6300A current for up to a maximum load of 33 kV.

Busbar Trunking System of L&T comes in a metal enclosure and is quite compact in size. It requires no maintenance and can easily last for more than 20 years. Compared to normal cabling, it requires much less space and can be installed within a very short time.

Sandwich Busbar Trunking System has a high tolerance to heavy voltage drop. It has single bolted copper or alumium busbars meant for 400A to 6300A current for a load of maximum 1000V.

Compared to Sandwich Busbar Trunking System, Conventional Busbar Trunking System is air-insulated. It has multi-bolted copper busbars housed in a 1.6 mm thick GI container having epoxy coating. Conventional Busbar Trunking System is meant for 100A to 400A current for an operating voltage upto 415V.

Larsen & Toubro has also Medium Voltage Busbar Trunking System for 400A to 5000A current for a load of 3.6 kV to 24kV. The enclosure is made of GI, Stainless Steel or Aluminium and is epoxy coated. The Busbars are made of Copper or Aluminium having multiple bolted splice plate joints.

All types of L&T Busbar Trunking Systems are ISO approved for their quality and for fire safety.

High Short Circuit Performance

Designed to handle up to 70 kA short-circuit for 1 second, the busbar trunking system provides exceptional safety and reliability for demanding power distribution environments. Its rigid construction and robust conductors ensure longevity and operational stability even under extreme electrical stresses.

Customizable for Various Applications

Whether you require different amperage ratings, lengths, or outlet configurations, the system is fully customizable. Accessories such as elbows, tee pieces, and end covers facilitate flexible layout changes, while modular construction allows expansion in both industrial and commercial setups.

Superior Safety and Fire Resistance

Tested according to IEC 60331, the systems fire resistance ensures continuity and protection under hazardous conditions. Integral earth busbar, fully enclosed live parts, and high dielectric strength supports further bolster safety standards, making it suitable for sensitive environments.

FAQs of Air Insulated Busbar Tunking System:

Q: How does the Air Insulated Busbar Trunking System ensure safety during a short circuit event?

A: The system is engineered to handle short-circuit currents up to 70 kA for 1 second, thanks to its rigid construction and robust copper or aluminum conductors. Enclosed, shrouded live parts and integral earth busbars enhance user safety in high-power distribution scenarios.Q: What customization options are available for the busbar system?

A: You can customize amperage ratings, section lengths, outlet types, number of poles (3 or 4), and choose between copper or aluminum conductors. Accessories such as elbows, tee pieces, and end covers allow tailored layouts based on site requirements and power needs.Q: Where can this busbar trunking system be installed?

A: It is suitable for both indoor and outdoor installations. With an IP54/IP55 rating as standard, and up to IP66 available on request, the system can be mounted horizontally or vertically on walls, floors, or ceilings in industrial and commercial locations.Q: What is the installation process for the system?

A: Installation is quick and flexible, utilizing pre-fabricated sections and tool-free tap-off options. Modular design allows for easy expansion and adjustment, with minimal maintenance required. Bolted clamp or plug-in joints facilitate secure connections.Q: When should temperature sensors be utilized for overheating protection?

A: Temperature sensors are recommended in applications where there is a risk of continuous high electrical load or where enhanced thermal monitoring is required. They provide overheating protection to ensure system integrity and prevent failure.Q: How does the systems fire resistance benefit the user?

A: Compliant with IEC 60331, the busbar trunking system remains functional during fire exposure, helping to maintain emergency power supply and improving overall safety in case of fire hazards.Q: What is the main benefit of choosing an air insulated busbar over traditional cabling for power distribution?

A: The busbar offers superior efficiency (>99%), lower voltage drop, expanded modularity, and minimal maintenance compared to traditional cables. It streamlines power distribution, especially in environments demanding high reliability and fast installation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Busbar Trunking System Category

Sandwich Busbar Straight Length (Feeder Type)

Price 3148-3523 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Product Type : Feeder Type Sandwich Busbar Straight Length

Application : Industrial Power Distribution, Commercial Panel Boards

Weight : Approx. 812 kg/m (depends on size & rating)

Dimension (L*W*H) : Standard Length 3m/6m, Width and Height as per rating

Sandwich Busbar Edgewise Elbow

Price 3148-3523 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Product Type : Sandwich Busbar Edgewise Elbow

Application : Electrical panels, switchgear busbar trunking systems

Weight : 1.2 kg

Dimension (L*W*H) : Customized, typically 300mm x 120mm x 120mm

Conventional Busbar Straight Length

Price 3148-3523 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Product Type : Busbar Straight Length

Application : Electrical Distribution

Weight : 5 kg per meter

Dimension (L*W*H) : 3000 mm x 50 mm x 10 mm

Medium Range Busbar Straight Length

Price 3148-3523 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Product Type : Straight Length Busbar

Application : Industrial Power Distribution

Weight : Approx. 6.0 kg/m

Dimension (L*W*H) : 4000 mm x 100 mm x 40 mm (Typical)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry