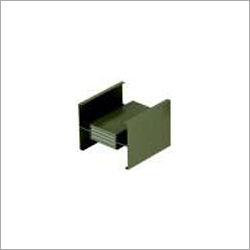

Conventional Busbar Flatwise Elbow

Price 3148-3523 INR/ Kilograms

Conventional Busbar Flatwise Elbow Specification

- Insulation Material

- PVC/Epoxy Coating

- IP Rating

- IP55

- Connector Type

- Bolt/Clamp

- Efficiency

- Over 98%

- Feature

- Corrosion Resistant, High Conductivity

- Overheating Protection

- YES

- Mounting Type

- Panel Mount

- Surface Finish

- Electro Tinned/Polished

- Shape

- Flatwise Elbow

- Humidity %

- Max 95% RH

- Power Factor

- 0.95

- Operating Temperature

- -10C to +85C

- Product Type

- Conventional Busbar Flatwise Elbow

- Application

- Electrical Panel, Distribution Boards

- Protection Level

- IP55

- Frequency (MHz)

- 50 Hz

- Rated Voltage

- 415 V

- Energy Consumption

- Low

- Output Type

- AC

- Color

- Red (Insulation Coat)

- Dimension (L*W*H)

- 150 mm x 50 mm x 6 mm

- Weight

- 1.5 kg

- Size

- Standard/Customizable

- Input Voltage

- 415 V

- Phase

- Three Phase

- No Of Poles

- 3

- Material

- Copper

- Connection Type

- Bolt/Clamp

- RoHS Compliant

- Yes

- Customization Available

- Yes (Size, Material, Coating)

- Standards

- IEC 61439 / IS 8623

- Current Rating

- Up to 1250A

- Compatible Bus Duct

- Available

- Bending Angle

- 90 Degrees

- Resistance to Short Circuit

- Yes

Conventional Busbar Flatwise Elbow Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Supply Ability

- 15000 Kilograms Per Month

- Delivery Time

- 1 Months

About Conventional Busbar Flatwise Elbow

Ganpati Electricals Pvt. Ltd. is a business partner of Larsen & Toubro for Bus Bar Trunking System, which is used in hotels, data centers, hospitals, airports, industries, factories, apartments etc. Electrical busbar systems are a modular approach to electrical wiring.

Busbar Trunking System is a prefabricated electrical distribution system consisting of busbars in a protective enclosure, including straight lengths, fittings, devices and accessories. These are mainly of two types namely Air-Insulated Trunking Busbar System and Sandwich Trunking Busbar System.

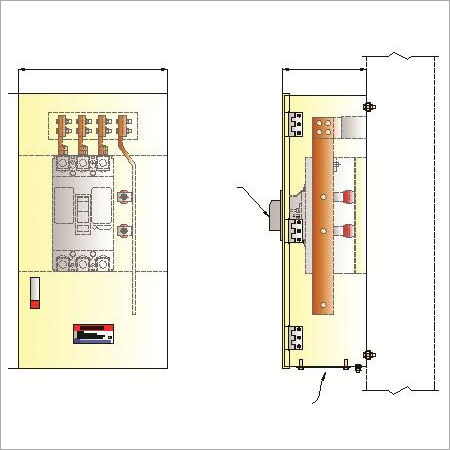

Sandwich Busbar Trunking System is epoxy insulated and used for transferring 400A to 6300A current for up to a maximum of 1000V. Compaired to this Conventional Busbar Trunking System is air insulated and is used for 100-400A current for upto a maximum of 415V. Besides these two, there comes also air-insulated Medium Voltage Busbar Trunking System for 100A to 6300A current for up to a maximum load of 33 kV.

Busbar Trunking System of L&T comes in a metal enclosure and is quite compact in size. It requires no maintenance and can easily last for more than 20 years. Compared to normal cabling, it requires much less space and can be installed within a very short time.

Sandwich Busbar Trunking System has a high tolerance to heavy voltage drop. It has single bolted copper or alumium busbars meant for 400A to 6300A current for a load of maximum 1000V.

Compared to Sandwich Busbar Trunking System, Conventional Busbar Trunking System is air-insulated. It has multi-bolted copper busbars housed in a 1.6 mm thick GI container having epoxy coating. Conventional Busbar Trunking System is meant for 100A to 400A current for an operating voltage upto 415V.

Larsen & Toubro has also Medium Voltage Busbar Trunking System for 400A to 5000A current for a load of 3.6 kV to 24kV. The enclosure is made of GI, Stainless Steel or Aluminium and is epoxy coated. The Busbars are made of Copper or Aluminium having multiple bolted splice plate joints.

All types of L&T Busbar Trunking Systems are ISO approved for their quality and for fire safety.

Robust Electrical Integration

Ideal for demanding electrical infrastructure, the busbar flatwise elbow ensures secure connections within electrical panels and distribution boards. Its IP55 protection safeguards against dust and water ingress, making it suitable for harsh environments across industrial and commercial settings in India.

Customizable for Versatility

This busbar elbow accommodates varying project requirements through options to customize size, material, and insulation coating. Suitable for three-phase applications and panel mounting, it can meet specific installation needs while consistently maintaining high conductivity and energy efficiency.

Engineered for Safety and Efficiency

With excellent short circuit resistance, overheating protection, and RoHS compliance, the flatwise elbow upholds the highest safety and environmental standards. Its copper construction and electro-tinned surface offer superior conductivity, corrosion resistance, and over 98% operational efficiency.

FAQs of Conventional Busbar Flatwise Elbow:

Q: How is the Conventional Busbar Flatwise Elbow installed in electrical panels or distribution boards?

A: The flatwise elbow is typically mounted using bolts or clamps, ensuring a secure and robust connection to electrical panels or distribution boards. Its panel-mounting design allows it to be easily integrated into existing systems.Q: What customization options are available for the busbar flatwise elbow?

A: You can order this product with customized size, material, and surface coating (electro tinned or polished) to match your specific project requirements. The insulation material can also be chosen between PVC and epoxy coatings.Q: When should I use a 90-degree flatwise elbow in my electrical setup?

A: A 90-degree flatwise elbow is ideal when your power distribution layout requires a right-angle turn without compromising on safety, conductivity, or space optimization. It effectively handles bends in busduct systems within electrical panels.Q: Where is this busbar elbow commonly used?

A: It is predominantly used in electrical panels, power distribution boards, and bus duct systems, especially in commercial and industrial electrical installations that need efficient and reliable three-phase power flow.Q: What is the process for ensuring the product meets safety and efficiency standards?

A: Each busbar elbow adheres to IEC 61439 and IS 8623 standards. They undergo rigorous testing for short-circuit resistance, overheating protection, and are RoHS compliant. This guarantees reliable performance and operational safety.Q: How does the product benefit my electrical distribution system?

A: With a high efficiency rate of over 98%, resistance to corrosion, and superior thermal performance, the busbar elbow reduces energy losses, increases system longevity, and minimizes maintenance requirements, resulting in lower overall operational costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Busbar Trunking System Category

Sandwich Busbar Plug-in Box

Price 3148-3523 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Product Type : Sandwich Busbar Plugin Box

Application : Industrial Electrical Distribution

Humidity % : 95%

Shape : Rectangular

Air Insulated Busbar Tunking System

Price 3148-3523 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Product Type : Air Insulated Busbar Trunking System

Application : Industrial, Commercial Power Distribution

Humidity % : 95% RH

Shape : Rectangular

Sandwich Busbar Flatwise Offset

Price 3148-3523 INR / Kilograms

Minimum Order Quantity : 500 Kilograms, ,

Product Type : Sandwich Busbar

Application : Power Distribution, Switchgear Panels, Electrical Enclosures

Humidity % : Up to 95% Noncondensing

Shape : Flatwise Offset

Sandwich Busbar Tunking System

Price 3148-3523 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Product Type : Sandwich Busbar Trunking System

Application : Industrial Power Distribution, Commercial Buildings, Data Centers

Humidity % : Up to 95% noncondensing

Shape : Rectangular

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry