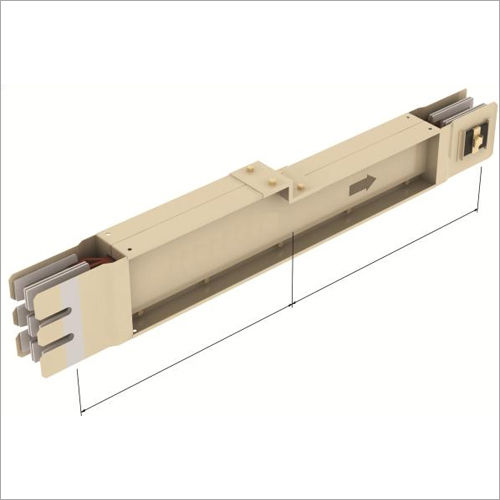

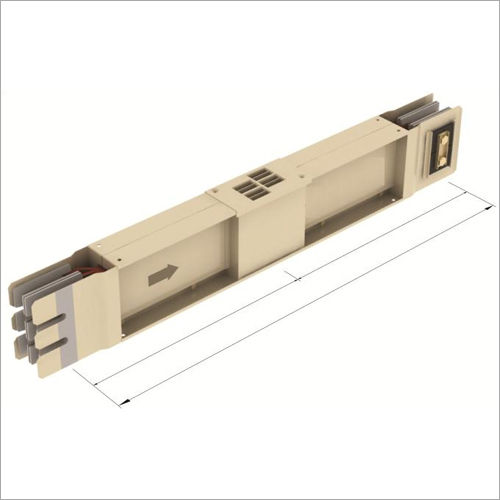

Sandwich Busbar Straight Length (Plug-in-Type)

Price 3148-3523 INR/ Kilograms

Sandwich Busbar Straight Length (Plug-in-Type) Specification

- Humidity %

- Up to 95% RH

- Shape

- Rectangular

- Efficiency

- >98%

- Operating Temperature

- -20C to +55C

- Overheating Protection

- YES

- Feature

- Dust-proof, Compact Design, Modular Extension

- Mounting Type

- Horizontal/Vertical

- IP Rating

- IP54/IP55

- Insulation Material

- Epoxy/Epoxy-resin

- Power Factor

- >0.95

- Connector Type

- Spring/Clamp Type

- Surface Finish

- Powder Coated

- Product Type

- Sandwich Busbar Straight Length (Plug-in-Type)

- Application

- Industrial/Commercial Power Distribution

- Protection Level

- High

- Frequency (MHz)

- 50/60 Hz

- Rated Voltage

- 400-690 V

- Energy Consumption

- Low

- Output Type

- Multiple outputs via plug-in units

- Color

- Grey/Red

- Dimension (L*W*H)

- Standard lengths: 3m/6m; Width: 65-110 mm; Height: 45-90 mm

- Weight

- Approx. 12 kg/m

- Input Voltage

- 400-690 V

- Size

- Various sizes as per rating

- Phase

- Three Phase

- Material

- Copper/Aluminum Busbars, Steel Enclosure

- Connection Type

- Plug-in type

- No Of Poles

- 3P/4P

- Expansion Capability

- Expandable modular system

- Fire Resistance

- IEC60332-1 compliant

- Ambient Temperature

- 20C to +55C

- Maintenance

- Low maintenance required

- Mechanical Strength

- High-impact steel casing

- Dielectric Strength

- >2500V

- Corrosion Resistance

- Anti-corrosive coating

- Creepage Distance

- As per IEC standards

- Busbar Current Rating

- 100A5000A

- Short Circuit Withstand Rating

- Up to 50kA

Sandwich Busbar Straight Length (Plug-in-Type) Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Supply Ability

- 15000 Kilograms Per Month

- Delivery Time

- 1 Months

About Sandwich Busbar Straight Length (Plug-in-Type)

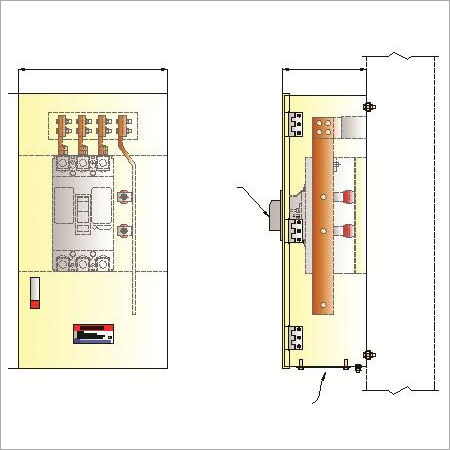

Ganpati Electricals Pvt. Ltd. is a business partner of Larsen & Toubro for Bus Bar Trunking System, which is used in hotels, data centers, hospitals, airports, industries, factories, apartments etc. Electrical busbar systems are a modular approach to electrical wiring.

Busbar Trunking System is a prefabricated electrical distribution system consisting of busbars in a protective enclosure, including straight lengths, fittings, devices and accessories. These are mainly of two types namely Air-Insulated Trunking Busbar System and Sandwich Trunking Busbar System.

Sandwich Busbar Trunking System is epoxy insulated and used for transferring 400A to 6300A current for up to a maximum of 1000V. Compaired to this Conventional Busbar Trunking System is air insulated and is used for 100-400A current for upto a maximum of 415V. Besides these two, there comes also air-insulated Medium Voltage Busbar Trunking System for 100A to 6300A current for up to a maximum load of 33 kV.

Busbar Trunking System of L&T comes in a metal enclosure and is quite compact in size. It requires no maintenance and can easily last for more than 20 years. Compared to normal cabling, it requires much less space and can be installed within a very short time.

Sandwich Busbar Trunking System has a high tolerance to heavy voltage drop. It has single bolted copper or alumium busbars meant for 400A to 6300A current for a load of maximum 1000V.

Compared to Sandwich Busbar Trunking System, Conventional Busbar Trunking System is air-insulated. It has multi-bolted copper busbars housed in a 1.6 mm thick GI container having epoxy coating. Conventional Busbar Trunking System is meant for 100A to 400A current for an operating voltage upto 415V.

Larsen & Toubro has also Medium Voltage Busbar Trunking System for 400A to 5000A current for a load of 3.6 kV to 24kV. The enclosure is made of GI, Stainless Steel or Aluminium and is epoxy coated. The Busbars are made of Copper or Aluminium having multiple bolted splice plate joints.

All types of L&T Busbar Trunking Systems are ISO approved for their quality and for fire safety.

Efficient Power Distribution

The Sandwich Busbar provides energy-efficient power distribution for both industrial and commercial sectors. Its compact, modular design allows for expansions or upgrades without extensive downtime, ensuring maximum adaptability. Thanks to its multi-output, plug-in configuration, power delivery to different equipment or production lines can be quickly configured and maintained.

Robust Safety and Fire Protection

Constructed for high mechanical strength and tested to IEC60332-1 for fire resistance, this busbar is well-suited for environments where safety and regulatory compliance are critical. Its high dielectric and corrosion resistance, along with its dust-proof and powder-coated enclosure, further guarantee longevity and safe operation.

Low-Maintenance and Reliable Performance

Engineered for longevity, the busbar features an anti-corrosive coating and epoxy-resin insulation. Maintenance requirements are minimalperformance is maintained over years of use, even in harsh environmental conditions with humidity up to 95% RH.

FAQs of Sandwich Busbar Straight Length (Plug-in-Type):

Q: How is the Sandwich Busbar Straight Length installed in industrial environments?

A: Installation is simplified through its plug-in-type connectivity and modular extension options. The busbar can be mounted horizontally or vertically, fitting into various layouts. Standard lengths (3m/6m) and ratings (100A5000A) accommodate most industrial or commercial setups.Q: What fire resistance and safety certifications does this busbar comply with?

A: The busbar system is IEC60332-1 compliant, ensuring superior fire resistance. It also provides high-impact protection, a dust-proof enclosure, and IP54/IP55 ingress protection for robust safety in demanding environments.Q: When should a modular, expandable busbar system be chosen over traditional cable wiring?

A: Modular busbars are ideal in settings requiring frequent expansion, minimal maintenance, and rapid installation. They are preferred for high-current applications (up to 5000A) where reliability, flexibility, and safety are top priorities.Q: Where can the Sandwich Busbar be used?

A: This system is suitable for power distribution in a wide range of industrial and commercial locations, including factories, warehouses, data centers, and commercial buildings across India, particularly those demanding efficient, reliable operation and expansion capability.Q: What is the process for expanding the busbar system with additional outputs?

A: Expansion is straightforwardadditional plug-in units can be installed without disrupting the main system. The modular design enables effortless scalability and future-proofing for changing load requirements.Q: How does the busbar benefit power distribution and operational efficiency?

A: With efficiency greater than 98%, low energy consumption, and high power factor (>0.95), the system reduces electricity losses. It also offers easy maintenance and rapid fault isolation through modular plug-in units, minimizing operational downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Busbar Trunking System Category

Sandwich Busbar Tunking System

Price 3148-3523 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Product Type : Sandwich Busbar Trunking System

Application : Industrial Power Distribution, Commercial Buildings, Data Centers

Rated Voltage : 415 V, up to 690 V

Overheating Protection : Other, Yes, Integrated

Sandwich Busbar Plug-in Box

Price 3148-3523 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Product Type : Sandwich Busbar Plugin Box

Application : Industrial Electrical Distribution

Rated Voltage : 415 V AC

Overheating Protection : YES

Conventional Busbar Straight Length

Price 3148-3523 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Product Type : Busbar Straight Length

Application : Electrical Distribution

Rated Voltage : 660 V AC

Overheating Protection : YES

Sandwich Busbar Reducer

Price 3148-3523 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Product Type : Sandwich Busbar Reducer

Application : Electrical Power Distribution, Panel Boards, Switchgears

Rated Voltage : 690V AC

Overheating Protection : YES

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry