Call: 08045804888

Fire Proof Paints/Barriers/Sealants for Cables

Price 3148-3523 INR/ Kilograms

MOQ : 500 Kilograms

Fire Proof Paints/Barriers/Sealants for Cables Specification

- Overheating Protection

- Yes (Thermal Expansion - Intumescent Action)

- Mounting Type

- Brush, Trowel, Cartridge or Spray Applicator

- Operating Temperature

- -5C to +60C

- Efficiency

- Standard industry efficiency for fire resistance

- Surface Finish

- Smooth/Matte after application

- Humidity %

- Max 95% RH, Non-Condensing

- Shape

- Paste/Liquid/Gel

- IP Rating

- IP65/IP66 Possible Post Application

- Feature

- Smoke Sealant, Fire Barrier, Intumescent, Halogen Free, Low VOC

- Insulation Material

- Intumescent acrylic or epoxy resin compound

- Product Type

- Fireproof Paint/Barrier/Sealant for Cables

- Application

- Protection of Electrical Cables, Penetrations, and Cable Trays in Fire-Prone Areas

- Protection Level

- Up to 2 Hours (120 Minutes) Fire Resistance

- Energy Consumption

- No direct energy consumption

- Color

- White, Grey, Red or as per requirement

- Dimension (L*W*H)

- Custom based on package (standard 5 Litre, 20 Litre containers)

- Weight

- Approx. 1-3 kg/litre

- Size

- Custom (based on requirement)

- Material

- Intumescent Fireproof Formulation (Acrylic or Epoxy Based)

- Shelf Life

- Minimum 12-18 Months (unopened, original container)

- Application Tools

- Brush, Spatula, Cartridge Gun, Spray

- Chemical Resistance

- Resistant to mild acids, alkalis, water

- Re-coating Interval

- Minimum 4 hours between coats

- Expansion Ratio

- Up to 40x original thickness on heating

- Storage Condition

- Cool, Dry Place; Protect from Freezing

- Drying Time

- Touch Dry: 2 hours; Full Cure: 7 days at 27°C

- Water Resistance

- High (once cured)

- Toxicity

- Low; Halogen Free, Asbestos Free, Non-Toxic Fumes

- Standards Compliance

- UL, IS:12458, ASTM E814, BS476 Part 20/22, EN1366-3

- Serviceable Temperature (After Curing)

- -30°C to +85°C

- VOC Content

- <60g/litre (Low VOC)

- Packaging Type

- Plastic/Metal Buckets, Cartridges, Pails

- Density

- 1.35 - 1.50 g/cm³

- Adhesion

- Excellent to Plastics, Metal, Concrete, Masonry

Fire Proof Paints/Barriers/Sealants for Cables Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Supply Ability

- 15000 Kilograms Per Month

- Delivery Time

- 1 Months

About Fire Proof Paints/Barriers/Sealants for Cables

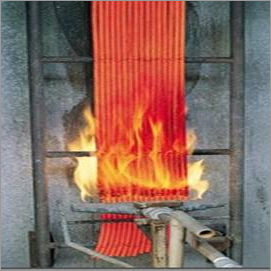

Fire Proof Paints / Barriers / Sealants for Electrical Cables

We provide world class fire stop solutions to achieve fire protection. These are available in form of paints, sprays, foams and flexible sealants etc. All these have proved to be most economical, maintenance-free and most reliable to protect cables from any kind of accidental fire.

Superior Fire Protection for Cables

Our fireproof coatings are specifically engineered for protecting electrical cables, penetrations, and cable trays in high-risk fire zones. Complying with global safety standards, these intumescent products expand on heating, effectively insulating and sealing vulnerable areas. Suitable for new and retrofit projects, they offer lasting fire resistance and peace of mind to facilities managers and electrical contractors.

Easy Application and Versatile Packaging

Apply the fireproof sealant with a brush, spatula, cartridge gun, or spray for a seamless, smooth/matte finish. Available in plastic or metal buckets, cartridges, or pails in custom sizes, the product is user-friendly for both small and large-scale installations. It requires a minimum 4-hour recoating interval and provides exceptional adhesion to most industrial surfaces.

FAQs of Fire Proof Paints/Barriers/Sealants for Cables:

Q: How does intumescent fireproof paint protect electrical cables during a fire?

A: Intumescent fireproof paint reacts to high temperatures by expanding up to 40 times its original thickness. This expansion forms an insulating barrier around cables, slowing down heat transfer, blocking smoke, and maintaining circuit integrity for up to 120 minutes.Q: What standards do these fireproof paints and sealants comply with?

A: Our products comply with UL, IS:12458, ASTM E814, BS476 Part 20/22, and EN1366-3 standards, ensuring reliable fire protection across various industrial regulations and requirements.Q: When can the painted or sealed cables be put back into service after application?

A: Cables can be handled when the coating is touch dry, which takes approximately 2 hours at 27C. However, for full fire resistance and performance, a curing time of 7 days is recommended before putting the assembly fully back into service.Q: Where is the best location to store unopened fireproof sealant containers?

A: Store the original, unopened containers in a cool, dry place, protected from freezing. This ensures a shelf life of 12-18 months and keeps the product in optimal condition for use.Q: What are the advantages of using this fireproof cable sealant in industrial or commercial premises?

A: Benefits include up to 2 hours of fire resistance, non-toxic and low-VOC formulation, robust adhesion to varied substrates, resistance to water, chemicals, and mechanical stress, and suitability for use even in high-humidity environments up to 95% RH, non-condensing.Q: How should the fireproof coating be applied for the best results?

A: For optimal results, apply the sealant or paint using a brush, spatula, cartridge gun, or spray, ensuring a minimum 4-hour interval between coats. Allow a full curing period of 7 days at 27C for maximum fire protection.Q: What packaging options are available for distributors and suppliers in India?

A: We offer packaging in plastic or metal buckets, cartridges, and pails in standard sizes (5 or 20 litres) or as per custom requirements, making them ideal for suppliers, traders, and wholesalers across India.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry